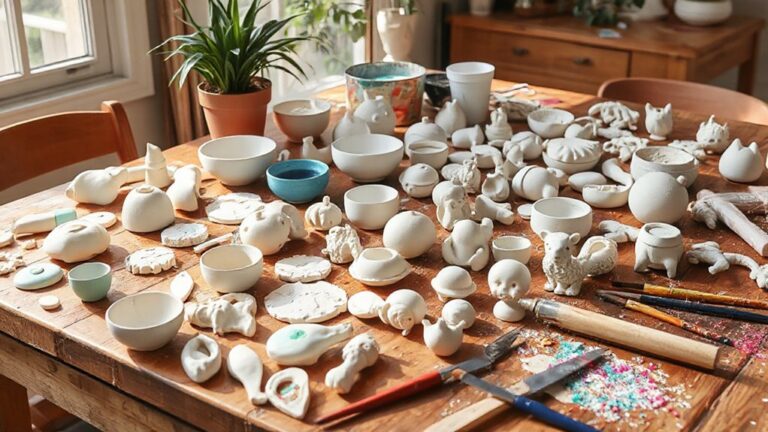

Make an Air Dry Clay Jewelry Holder in 7 Steps

I’ll help you make a heart-shaped air dry clay jewelry holder in 7 steps: roll clay to 1/4-inch between dowels, trace and cut a heart template, smooth edges with a damp finger, let it rest 20 minutes to firm up, roll an even coil for the wall, score both edges and add slip before joining and blending seams, then dry flat for 24 hours before painting and sealing. Stick around for extra finishing tips and options.

Key Takeaways

- Roll air dry clay to 1/4-inch thick using dowels and an acrylic rolling pin for an even, sturdy jewelry holder base.

- Trace a heart template with a needle tool, cut with a craft knife, lift with a scraper, and smooth edges with a damp fingertip.

- Let the cut shape rest 20 minutes to even moisture, improve adhesion, and reduce warping during wall-building.

- Roll an even coil for the sides, wrap around the base edge, angle-cut the ends, and press gently for a balanced rim.

- Score, add slip, re-score, and blend seams with ribs; dry flat for 24+ hours, avoiding paper to prevent sticking.

Tools + Materials for an Air Dry Clay Jewelry Holder

Before I even touch the clay, I like to lay out my “mini clay toolkit” so everything’s within reach and I’m not scrambling mid-project. For clay types, I stick with air dry clay, and I wedge any old clay first so it feels smooth and ready. I grab 1/4-inch dowels and an acrylic rolling pin, plus a heart template for consistent shapes. For clean crafting techniques, I use a scoring tool, serrated metal rib, fettling knife, and rubber rib. I also mix slip (clay + water) to glue and strengthen seams. Later: acrylic paint, light modeling paste, and piping tips—craft-only.

Roll and Cut the Jewelry Holder Base (Template Method)

First up, I roll out my air dry clay to a nice, even 1/4-inch thickness by sandwiching it between two 1/4-inch dowels and gliding an acrylic rolling pin over the top (think “pie crust,” but smoother). Once the clay thickness feels consistent, I lay my heart template on top and trace around it with a needle tool. Then I cut straight down with a craft knife for crisp edges—no sawing. I lift the heart gently with a scraper so it doesn’t stretch. If the edge looks rough, I smooth it with a damp fingertip.

Let the Base Firm Up (Why 20 Minutes Helps)

Once my heart shape is cut out, I like to let it sit for about 20 minutes so it can firm up a bit—think of it like letting cookie dough chill so it holds its shape better. This rest evens out moisture, improves clay consistency, and boosts structural integrity, so the base won’t warp when I press on it. It also makes scoring and slip stick better for clean, seamless joins.

| What I notice | Why it helps |

|---|---|

| Surface feels less sticky | Easier to handle together |

| Base stays flatter | Less bending or collapsing |

| Edges look calmer | Fewer cracks later |

Make the Side Coil for Your Air Dry Clay Jewelry Dish

With the base slightly firmer and easier to handle, I like to build the little “wall” that turns it into an actual dish. I roll a long coil and keep the coil thickness even, like a smooth rope, so the rim looks calm and balanced.

As I roll, I dip my fingers in water to stop brittleness and help the clay glide. Then I wrap the coil around the base edge, pressing gently so it hugs the shape without stretching. Where the ends meet, I slice them at an angle with a fettling knife for better joint strength.

Score + Slip to Join Seams (And Stop Cracking)

Although the coil might look like it’s already “stuck,” I never trust a plain press-and-pray seam—score and slip is what keeps that rim from popping off or cracking later. I use a scoring tool to scratch both edges; these scoring techniques give the clay “teeth” to grab.

Next, I paint on slip applications (clay + water) like glue. I let the slip thicken a bit, then re-score for an even stronger bond before pressing together. If the join feels weak, I add a tiny extra coil as reinforcement. Finally, I blend: rubber rib, then serrated metal rib, back and forth until the seam disappears.

Drying Times, Surfaces, and Warping Prevention

If you want your clay jewelry holder to stay flat and smooth instead of turning into a wavy little potato chip, drying is where you’ve gotta slow down and get picky. I stick to gentle drying techniques: no heat blasts, no direct sun, and I give it at least 24 hours to harden fully.

| Step | Surface selection | What I do |

|---|---|---|

| 1 | Wood/glass | Set it flat |

| 2 | Avoid paper | Stops peeling |

| 3 | Open air | Rotate sometimes |

Keep an eye on it, and we’ll get a smooth piece together.

Paint, Pipe Details, Then Seal (Varnish vs UV Resin)

Next, I pipe light, fluffy modeling paste with tip #2 for crisp swirls and dots. Let it all dry 24 hours. Then choose sealing options: clay varnish (easy, may yellow) or UV resin (super glossy). Seal evenly, paint the bottom, and don’t dry on paper.

Frequently Asked Questions

How Do I Remove Lint and Dust From the Clay Before Sealing?

I remove lint and dust by letting clay fully dry, brushing gently with a soft paintbrush, then wiping with a barely damp microfiber cloth. For lint removal and dust prevention, you’ll join me sealing only after it’s spotless.

Can I Add a Magnet or Hook for Hanging Jewelry?

Yes—you can add a magnet or hook for hanging jewelry. I once embedded a small neodymium magnet, and it held my studs perfectly. For magnet options, seal it. For hook placement, pre-drill and epoxy. You’ll fit right in.

Is This Holder Safe for Damp Bathrooms and High Humidity?

It’s not fully safe in damp bathrooms; air-dry clay lacks humidity resistance, so I’d seal it well for better bathroom durability. If you’re in our DIY circle, you’ll let it cure, paint, and seal again.

How Do I Repair Chips or Cracks After the Piece Has Dried?

Like stitching a tear in fabric, I’ll patch chips with fresh clay or filler: start with surface preparation—sand, clean, dampen. Apply repair techniques in thin layers, blend edges, let dry, then repaint, seal together.

Are There Allergy-Safe or Non-Toxic Sealers for Sensitive Skin?

Yes—I use water-based, AP-certified acrylic sealers or food-safe waxes; they’re allergy-safe for most sensitive skin. For natural finishes, I choose beeswax or carnauba. Patch-test first, and pick hypoallergenic options you trust.